Press working may be defined as, a manufacturing process by which various components are made from sheet metal. This process is also termed as cold stamping. The machine used for press working is called a press.

The main features of a press are:

- A frame which support a ram or a slide and a bed, a source of mechanism for operating the ram in line with and normal to the bed.

- The ram is equipped with suitable punch/punches and a die block is attached to the bed.

- A stamping is produced by the downward stroke of the ram when the punch moves towards and into the die block.

- The punch and die block assembly is generally termed as a “die set” or simple as the “die”

Press working operations:

The sheet metal operations done a press may be grouped into two categories.

1: Cutting operations

2: Forming operations

In cutting operations the work piece is stressed by its ultimate strength. The stresses caused in the metal the applied forces will be shear stresses. The cutting operations include:

(a) Blanking (b) Punching (c) Notching

(d) Perforating (e) Trimming (f) Shaving

(g) Slitting (h) Lancing

In forming operations , the stresses are below the ultimate strength of the metal , in this operation , there is no cutting of the metal but only the contour of the work piece is changed to get the desired product.

The forming operations include:

(a) Bending (b) Drawing (c) Squeezing

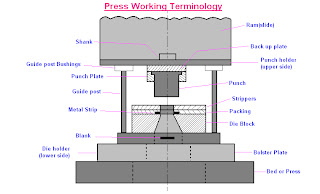

1: Bed:

The bed is the lower part of the press frame that serves as a table to which a

Bolster plate is mounted.

2: Bolster Plate:

This is a thick plate secured to the press bed , which is used for locating and

supporting the die assembly. It is usually 5 to 12.5 cm thick.

3: Die Set:

It is unit assembly which incorporates a lower and upper shoe, two or more guide parts and guide part bushings.

4: Die Block:

It is a block or a plate which contains a die cavity

5: Lower Shoe:

The lower shoe of the a die set is generally mounted on the bolster plate of a press. The die block is mounted on the lower shoe, also the guide post are mounted on it.

6: Punch :

This is male component of a die assembly, which is directly or indirectly moved by and fastened to the press ram or slide.

7: Upper Shoe:

This is the upper part of the die set which contains guide post bushings.

8: Punch Plate :

The punch plate or punch retainer fits closely over the body of the punch and holds it in proper relative position.

9: Back up Plate:

Back up plate or pressure plate is placed so that intensity of pressure does

not become excessive on punch holder. The plate distributes the pressure

over a wide area and the intensity of pressure on the punch holder is reduced

to avoid crushing.

10: Stripper:

It is a plate which is used to strip the metal strip from cutting a non-cutting

Punch or die. It may also guide the sheet.